- SITEMAP

- CONTACT US

- 8618267732328

News

Credibility ,the lifeblood of enterprise!

- Fittings

- Butt Welding Fittings

- Forged Fittings

- 180 Degree Elbows

- 90 Degree Elbows

- 60 Degree Elbows

- 45 Degree Elbows

- 30 Degree Elbows

- Equal Tee

- Reducing Tee

- Concentric Reducer

- Eccentric Reducer

- Lap Joint Stub End

- Outlets

- Cap

- Bend

- Cross

- Coupling

- Stainless Steel Lateral Tee

- Bellows Expansion Joints

- Flexible Metal Hose

- Non-Standard/Custom Fittings

- Bleed & Flushing Rings

- Types of Flanges

- Anchor Flanges

- Blind Flanges

- Expander Flanges

- High Hub Flanges

- Lap Joint Flanges

- Long Weld Neck Flanges

- Nipoflanges

- Orifice Flanges

- Plate Flanges

- Ring Type Joint Flanges

- Reducing Flanges

- Slip On Flanges

- Socket Weld Flanges

- Spectacle Blind Flanges

- Square Flanges

- Spades & Ring Spacers

- Threaded Flanges

- Welding Neck Flanges

Minimum Thicknesses, Negative Deviations for Plates and Pipes-ASME VIII-1

- (1) Plate heat exchanger heat transfer plate, ASME 2017 VIII-1 added a new mandatory appendix 45 plate heat exchanger, the appendix has a minimum thickness of the plate heat exchanger heat transfer plate requirements, the minimum nominal thickness required is 0.35mm (0.014in);

- (2) Casing heat exchangers with inner tubes, DN 150 (6in) or less in diameter; pipes and heat exchanger tubes inside the casing, casing or tubing, DN 150 (6in) or less in diameter; other pressurized parts of such equipment must meet the minimum thickness requirements in Question 1;

- (3) Cylinders and heads of unfired steam boilers (unfired steam boilers) with a minimum thickness of 6mm (1/4inch) (excluding any corrosion margin);

- (4) medium for compressed air (compressed air), steam (steam), water (water), from the table UCS-23 mile material manufactured cylinder and head, the minimum thickness is 2.5mm (3/32inch) (excluding any corrosion margin);

- (5) Heat exchanger tubes for air coolers and cooling towers and meet the following conditions:

- a) The heat exchanger tubes shall not be applied to lethal media (UW-2(a));

- b) The heat exchanger tube shall be protected by fins or other mechanical means;

- c) The minimum outside diameter of the heat exchanger tube is 10mm (3/8in) and the maximum is 38mm (1.5in);

- d) The minimum thickness should not be less than the required thickness calculated by UG-27 or Appendix 1-1 formula, and in any case should not be less than 0.5mm (0.022in).

- Required Thickness - the thickness calculated from the equations in the specification (without adding corrosion margins)

- Design Thickness - Required Thickness + corrosion allowance

- Nominal Thickness - the thickness selected at the time of purchase.

In the case of plate, the nominal thickness may be selected by the manufacturer, either as shown on the Material Test Report prior to forming, or as measured at the weld seam of the plate or at the location under consideration.

If pipe is procured at nominal thickness, the pipe shall be considered for fabrication negative deviation, but need not be considered when calculating the area of reinforcement required for receivers based on UG-37 and UG-40; fabrication negative deviation is given in some pipe grades, refer to Subsection C, which can be found below:

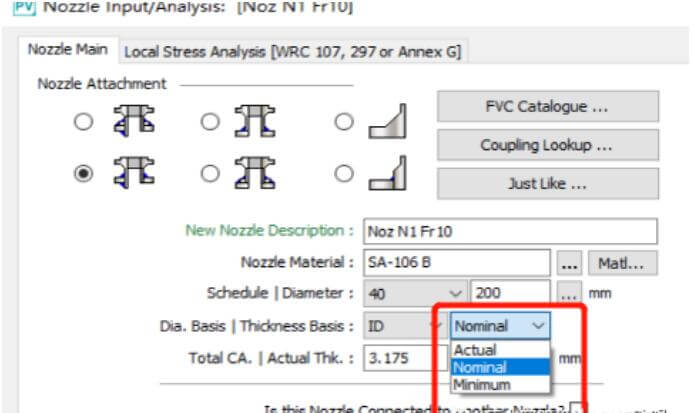

Revisiting the Takeover System of Units-Nominal\Actual\Minimum

In the application of PV Elite for open hole reinforcement calculations, there are three options in the software, Nominal\Actual\Minimum, many customers do not know how to choose or there are many wrong choices that may affect the future calculations, before combing through the options, first look at ASME VIII-1 UG-16(d), refer to the following content:

- 1. Nominal wall thickness, need to deduct negative machining deviation

- 2. based on UG-37 and UG-40 open hole reinforcement calculation, Nominal wall thickness does not need to deduct processing negative deviation.

In fact, PV Elite in the takeover of the three settings directly related to this, if you choose Nominal, based on the provisions of the code, in the UG-37 and UG-40 open hole reinforcement area calculation directly using the nominal thickness on the line, but the other wall thickness calculations, the minimum thickness of the neck calculations, etc. will be deducted from the negative deviation. If Actual is selected, the software assumes that a Non-Nominal pipe is selected, and ignores the provisions of UG-16(d), so the effect of negative machining deviation will not be taken into account in either the wall thickness or the open hole reinforcement calculations. If Minimum is selected, this means that the most conservative calculations will be made, and negative machining deviations will be deducted from both the open hole reinforcement calculations and the thickness calculations.

Tel No:+86-18267732328 / Email:[email protected]

Address:Longwan District, Wenzhou, Zhejiang Province, China.

Copyright Notice © www.yaang.com Yaang Pipe Industry Co., Limited All rights reserved.

Yaang Pipe Industry Co., Ltd. is an international supplier of piping solutions for flange, butt welding fittings, socket welding fittings and threaded fittings. Our products are widely used in different industrial fields, including oil and gas, chemical industry, petrochemical industry, power plant, pulp and paper industry, environmental and water conservancy engineering, engineering projects, etc.